Somos una compañía especializada en diseño, ingeniería y montaje de plantas y equipos de dosificación y mezcla para sólidos y líquidos

Construimos plantas adaptadas a los requerimientos específicos de nuestros clientes, aportando una larga experiencia en multitud de procesos industriales

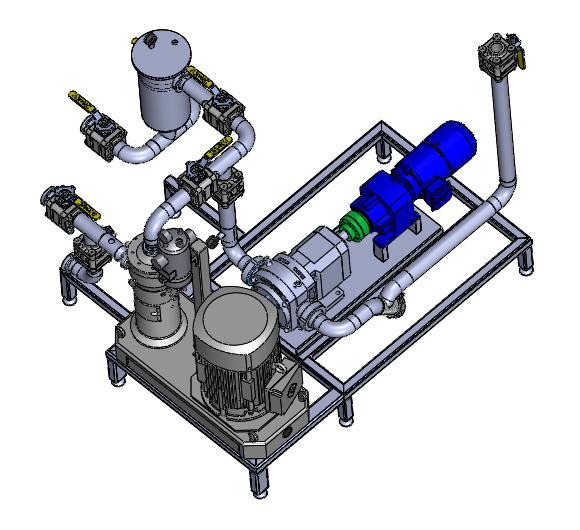

Equipos industriales de proceso

Soluciones para su industria

Proyectamos desde una simple mezcla de líquidos hasta la dosificación y mezcla múltiple de sólidos y líquidos implantando una instalación llave en mano.